The most widely used production method for creating plastic parts is injection molding. With raw plastic material, a variety of production parts, both large and tiny, long-lasting or disposable, can be created for numerous industrial uses. Thermoplastics are a good fit for the procedure because they can be heated until they are molten and then injected into a metal mold, where they cool and take on the shape of the cavity or interior of the mold.

The skilled staff at 3ERP creates the highest-quality injection molded parts. With the aid of rapid tooling and injection molding, 3ERP can rapidly and effectively produce intricate custom metal or plastic injection moldings and provide great Injection molding services. Injection Molding produces plastic or elastomeric elements with brilliant precision and keeps molding charges to a minimum.

Benefits and Drawbacks of the Injection Molding Process

Think carefully about the advantages and drawbacks of injection molding before figuring out whether or not to use it in your element.

Benefits of the Injection Molding Process

Efficient High Production

Once the molds have been created, the procedure is incredibly quick, with cycle times as low as 10 seconds. Depending on the molds you choose, it is suitable for medium and high-volume manufacturing runs. Consider an effective front-end design and order process if you are outsourcing your molding; have a look at our on-demand production.

Large Material Choice

You may choose from an extensive range of plastic materials depending on the features your very last product needs to have. Also available from Portola’s is liquid silicone rubber molding, so you are not confined to using plastic. A wide variety of colors are available, and you may even put fillers in the molding process to give the finished item more robustness. Speak with us about what you need your contribution to accomplish; there are usually a variety of possibilities.

Low Cost

The cost per part for large volume production runs is quite low. By using aluminum molds rather than steel ones, you can save costs even for medium volumes, or between 10,000 and 25,000 pieces. Numerous copies of the same product can be produced. This is the best choice if you need parts with precise tolerances and high levels of dependability.

Low Waste

When compared to numerous other production processes, the molding process generates a very small amount of waste. Even if there is any leftover plastic or trash, it can be recycled and used again. Under extremely high pressure, molten plastic is injected into the mold during the procedure.

Drawbacks of the Injection Molding Process

Initial Cost

It can take a lot of time and machining to make steel mold tools if you commit to them for large production volumes, and this can be a considerable capital expense. Your cost per part will change if you require fewer parts, so it may be worthwhile to look at other solutions, such as using aluminum molds.

Initial Lead Time

The manufacturing of steel tooling can take up to 12 weeks. By utilizing aluminum molds and digitizing our front-end process, we can ship anywhere between 25 and 10,000+ pieces within 15 working days or less from the time you first upload your CAD. Parts can sometimes be delivered in a single day.

Design Limitations

If aesthetics are important, you should also think about where to place your gates, ejectors, and cooling lines. Also, keep in mind that it's challenging to alter a mold's design; you can add plastic to your finished product or remove portions of the mold, but not the other way around. With 3D printing, you can create almost any shape or geometry you need for smaller production runs.

Sum Up

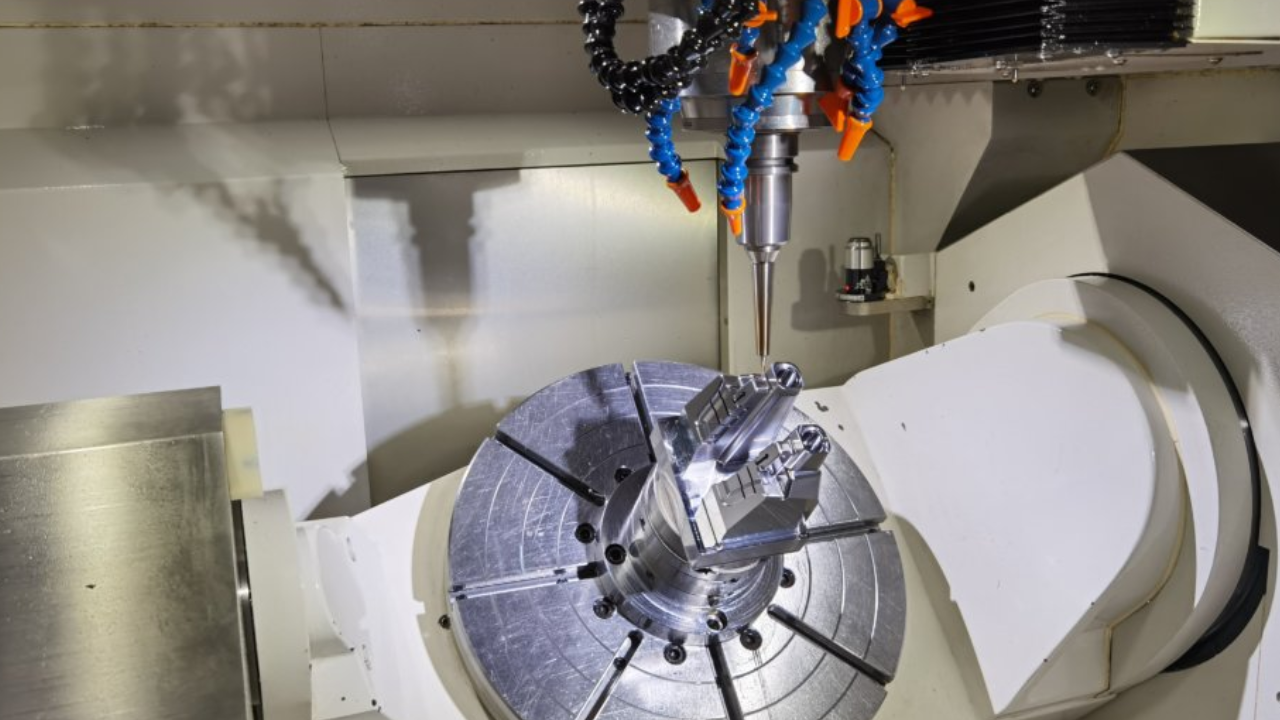

A great manufacturing technique for generating mid to high-volume items in plastic and liquid silicone rubber is injection molding. Since it is constantly changing, it is worthwhile to look into fresh concepts that can enable you to cut the cost of your parts for shorter manufacturing runs. It's also important to look at whether different technologies, like CNC or 3D printing, would be a better choice for small production runs or even specially-made items.